To be a global leader in providing high performance materials, and the solutions to realize their full application potential. We wish to push the boundaries of excellence in the additive manufacturing space.

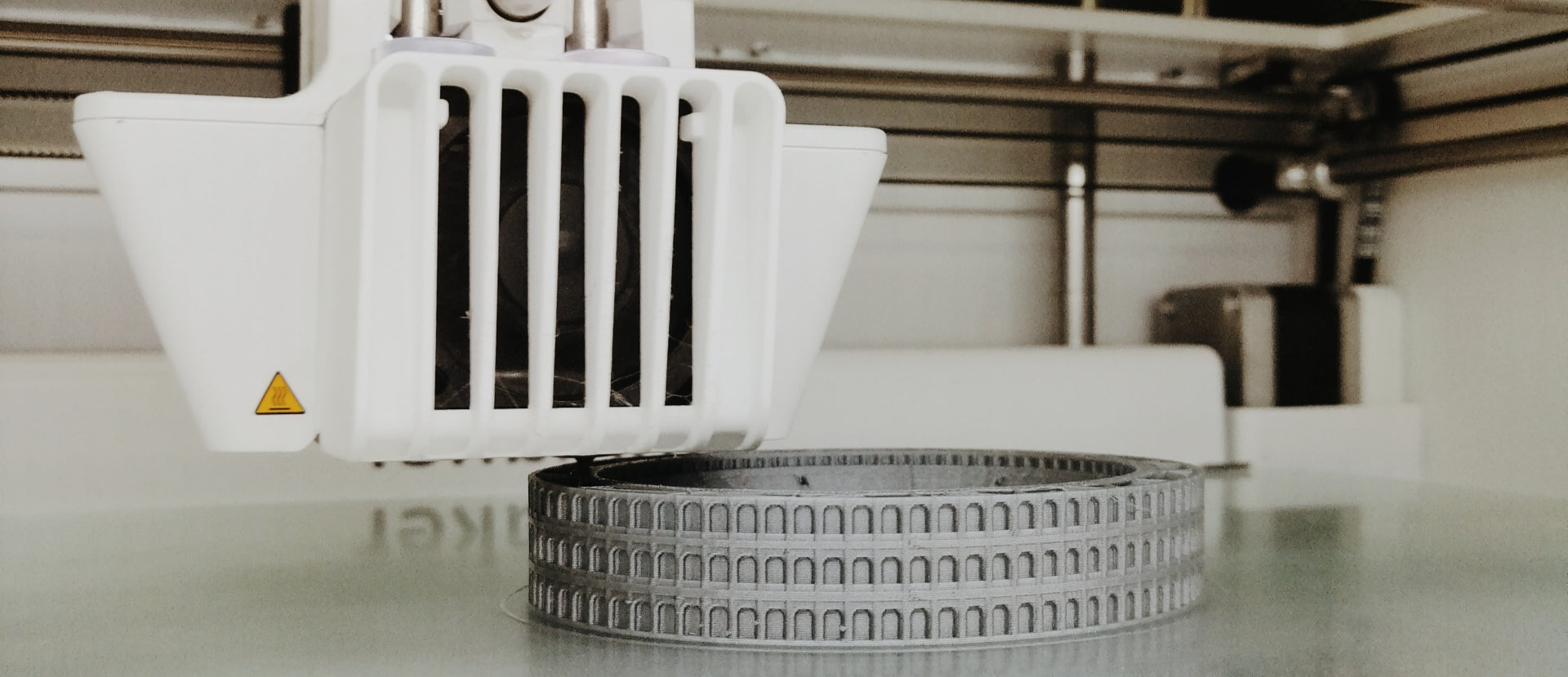

3DAMSS (3D Advanced Manufacturing Solutions And Services) is a company from Dubai, the city of innovation and the center of all trade and commerce in the Arabian peninsula, the company specializes in production of high-performance materials like PEEK/PEKK/PEI/PPSU and many others along with filled grades of the same, it has been our endeavor to produce materials of global standards, for industries such as aerospace, defense, medical, automotive to name a few, the company also provides 3d printing services for low volume parts and prototyping to customers, and has been distributing Intamsys machines since the start of their company.

We started off in the additive manufacturing world in our jewelry company, we used the SLA route to produce prototypes for casting parts, which lead us to research into FFF technologies, the initial application was to produce jigs and fixtures for our CNC machines which we use to produce our jewelry, it was during this journey we experimented with high performance materials and from there it branched out to making our own materials and also providing print services to customers around the globe.

We at 3damss have a policy about quality first profit margins later, our thrust has always been to provide better products for our customers, we strive to keep a strict diameter control and handle the materials in way, where the property loss is minimal, we are not afraid to experiment and constantly keep pushing the bar, like most competitors are only doing 10% carbon fiber loading in PEKK, we however have gone further and made a 20% loading.

The PEKK glass fiber filament has been a first from us, other competitors don’t have it yet in their portfolio, we also use higher fiber lengths, whereas our competitors generally use lower lengths, this is done by them to increase output and lower their costs, we also have medium fibers as well which are suited for customers with lower printing experience and also who do not have machines which have the capability to process higher length fibers, for the maintaining this kind of quality we generally sacrifice output as quality comes first, also many of our competitors use off-specification materials from resin makers at lower costs to maximize profit.

However this is not our philosophy and we work with only genuine virgin materials from trusted suppliers like mentioned above, and overall we offer competitive prices which are generally slightly lower than competition despite giving a better quality product to the customer.

We plan to expand our capacities and product portfolio to reach more markets, we aim to do this by creating more partnerships worldwide, there will be partnerships with resellers for marketing our materials and also universities for research into future materials, which will benefit us in the future. We also plan to open a facility in India as well, to cater to the large Indian market, and perhaps have production centers worldwide, like Europe Americas and a Apac location, along with our existing middle east production facility, for the Australian market we have joined hands with a young Australian start up for distributing our materials.

RAJIL PAHUJA

Founder and CPO

RAJIL PAHUJA

Founder and CPO

Rajil has been associated with additive manufacturing for the last 10 years What started as a hobby after stumbling upon NASA white paper, has quickly turned into a full fledged business proposition. Rajil started experimenting making 3D parts for his jewelry business which lead him to experiment with different filaments to make the most suitable filament. That lead to the birth of 3DAMSS.

Monil Pahuja

Co-founder and COO

Monil Pahuja

Co-founder and COO

Monil has over 2 decades of Industrial manufacturing expertise and is experienced with multiple industrial manufacturing technologies. He has extensively travelled to manufacturing ecosystems in Europe to gain access and experience on some of the best engineered production platforms in subtractive manufacturing.

We use materials from only internationally reputed suppliers like Sabic/Arkema/Gharda, these companies are at the forefront of innovation in high-performance polymers, and we use the best manufacturing practices to produce the best quality filament available on the market, with very strict diameter control using melt pumps and mesh filtration and a specialized process to ensure the polymers keep their property loss at a minimum during processing, it is our policy not to sell any material that has been processed twice, however being a responsible company the materials are used for making sample parts meant for marketing materials, so as to reduce our ecological footprint, for our compounding need.